Aurora Amenity Center

Green Valley Ranch, CO

Design Firm | EVStudio

VIEW IFC SET

(Drone Photo - Contractor-Supplied - Southwest Corner)

Within the Commercial studio, this project was my first project at EVStudio to break ground and achieve Substantial Completion. Woohoo!

This Amenity Center was my first exposure to designing around and coordinating with the engineers of Pre-Engineered Metal Building (PEMB). This offered completely new opportunities and challenges than the typical wood stud- and steel-framed structures I had previously designed.

While achieving an Exterior Thermal Envelope that is easily finished and installed is a tricky challenge, the unique 3-Dimensional "waterfalling" form of the Elevation offers unique methods of introducing natural light, interior decor and HVAC equipment to the interior spaces.

Nestled nearby and servicing a truly massive development of over 900 Single Family production homes, this Amenity Center provides rentable Community Party spaces. It also has a Fitness Center and exterior Pool for use by all tenants. Located within a predominantly Agricultural area of Aurora, the design aesthetic is a "Modern Farmhouse" style. With its white Board and Batten walls, standing seam shed roofs at covered porticos, and long, tiered forms, this rustic Amenity Center stays rooted in its farming environment.

My contributions to this project were primarily—but not limited to—the following:

-

STRUCTURAL COORDINATION | Worked alongside with and accommodated PEMB Framing and Rough Openings into design.

-

LOCKER ROOM LAYOUT & FIXTURES| Crafted designs to maximize flow and cut off lines of sight.

-

IECC COMPLIANCE | Detailed insulation systems applied outside of PEMB-framing at walls and roofs.

-

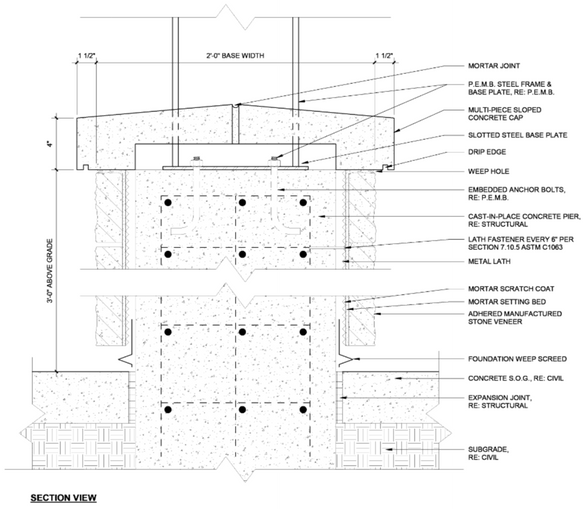

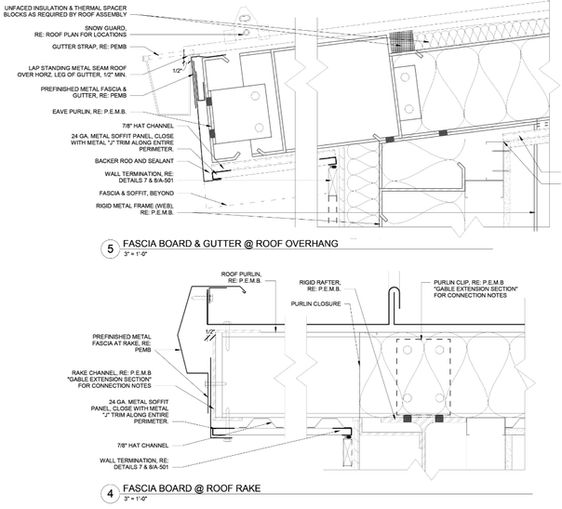

DETAILING | Drafted a full suite of Architectural & connection-to-PEMB detail drawings.

-

POST-PERMIT | Handled RFIs, Submittal reviews & revisions, and cross-discipline coordination during Construction Administration.

(Drone Photo - Contractor-Supplied - Northeast Corner)

1 | Exterior Envelope Forms by PEMB Designer

The flowing roof forms are dictated by the PEMB-designer's drawings, thus all roof heights, overhangs, and slopes were pre-determined. Architectural details and designs were chosen to accommodate. Additionally, all exterior openings—both windows and doors—were set by the PEMB design and all items had to be custom-designed and fit during Shop Drawings and site installation. This is atypical in the AEC industry.

2 | Pool Layout Revised during Post-Construction Design

The form and layout of the pool, designed by a separately-contracted Commercial Pool Designer, was revised after the obtaining of Building Permit. That is why viewers will notice a discrepancy of the pool layout in the Renders and construction photos.

3 | Separated Pool House and Chemical Areas

Upon deeper inspection, one may notice that the interior general-public areas are separated from the Pool Chemical spaces via a breezeway. This was done to create a secure entry to the pool from the exterior and a buffer between the general public and hazardous chemicals stored within the Chemical Spaces. These areas are protected by Fire-Rated partitions and chemical spill containment measures such as concrete curbs and raised door thresholds.

AMENITY CENTER

This 6,400 square-foot PEMB structure is a single-story building with three separate roof planes that are built directly into a continuous steel frame. This robust structure allows for a column-less interiors and wide open areas—both horizontally and volumetrically—that accommodate fitness, event, and gathering spaces to serve the community.

A continuous steel structure and roofline unites the separated Clubhouse and Poolhouse spaces around a secured exterior breezeway. Here, occupants from either space or those entering from the residential community can access the pool without entering the Amenity Center.

A portico on the East face is nestled alongside the outdoor pool and provides shaded seating as well as a second entrance directly from the main Community / Party space. To the pool's north, swimmers can access public restrooms, showers, and storage lockers. The portico on the West face provides seating and coverage immediately adjacent to visitor parking.

4 | Separated Pool House and Chemical Areas

RESTROOM DESIGN

When I took over for this project in the early DD phase, one of my first tasks was to completely re-design the locker rooms to cut down on sightlines from adjacent spaces. The new design provides a linear flow from fitness entry to pool exit, and most importantly, achieves a layout that meets ISPSC code-minimums for fixtures.

As this was the primary restroom of the Amenity Center, it had to meet ISPSC mandates for the occupancy of the Pool as well as IBC for the building occupants. As such, the viewer will understand why their are so many fixtures for a building footprint of this size.

Additionally, the restrooms, showers, and lockers are designed to be used in tandem by gym-goers and swimmers, and as such, this linear layout was proposed. The clever use of furred-walls, wing walls, and positioning of door swings obstructed any outside views into the Locker rooms.

See the interior elevations and finish photos below for a better sense of the spaces' feel.

5 | Interior Elevations - Men's Locker / Restroom

FINISHES

Finish Photos - Fitness Area, Locker Rooms & Breezeway

INTERIOR DESIGN

Finish Photo Gallery

Finish Plan

6 | Enlarged Plan - Community Room Kitchenette

7| Interior Elevations - Community Room Kitchenette

SITE WALKS - CONSTRUCTION PHOTOS

5 | Site Photos - Chronological - PEMB Framing to Dry-In to Substantial Completion

CONSTRUCTION ADMINISTRATION

I was responsible for the bulk of the responsibility during the Construction Administration phase. The handled the following tasks with minimal action or oversight by the project architect:

-

Reviewing Product Submittals and recommending suggested alternatives when needed

-

Reviewing Contractor RFIs and making necessary drawing changes

-

Altering CD detail drawings for added plumbing services at un-insulated roofs

-

Coordinating and solving cross-discipline conflicts from MEP designs

-

Attending weekly Owner-Architect-Contractor (OAC) meetings

-

Conducting periodic Site Visits

-

Catching conflicts with Thermal Envelope requirements + offering solutions

Construction began in January 2025 and is concluding in November 2025. However, the Amenity Center began operations in early October 2025. The 6,400 square-foot facility was finished in nearly 10 months.

Taylor Kohrs Construction was the general contractor for this project. I was in near daily-contact with their Superintendents and Project Engineers to coordinate MEP-design issues and ensure the continuous advancement of the construction timeline. The biggest issue accounted during construction was the lack of continuous insulation installed at exterior walls. This was remedied by proving that, if substituting batt insulation with spray foam insulation, the average U-factor of the wall would be code compliant.

DETAILS

While I creating the standard suite of project details, I was presented the opportunity to prepare unique waterproofing and door details such as:

-

EXTERIOR FINISHES & OPENINGS | Prepared details that properly insulated, water-proofed and accommodated structure within the Thermal Envelope and building fenestrations. All was carefully done to match the PEMB drawings that had been permitted already.

-

CHEMICAL CONTAINMENT | Detailed bases of walls, thresholds of doors, and fire-rated enclosures in order to contain hazardous chemicals.

-

INTERIOR PERIMETER | Created a contemporary space by partially masking structure and in-wall utilities with furrs and column wraps.

-

ROOF FINISHES | Created insulation systems and brake-metal finishes to encapsulate a PEMB system that was previously permitted.

Typical Plan & Section Details - Finishes and Framing

PROJECT BLOG POSTS

ANALYSIS BY LITERATURE

Writing about one's own architectural projects is a lost art that has been handed over marketing teams and online publishers. At EVStudio, we were fortunate to be given the opportunity to blog about the construction progress, lessons learned and challenges experienced.

By sitting down and synthesizing the entire design lifespan into a few short paragraphs, an architectural professional is forced to recapture and re-evaluate the design intent that transformed a thought in their heads into a completed, fully-realized structure.

Below, you will find three separate articles I authored to document ongoing construction progress for the Aurora Amenity Center:

Green Valley Ranch Amenity Center - A Fully Dried-In Exterior Shell

Published: August 25, 2025

Green Valley Ranch Amenity Center - A Fully Assembled PEMB Frame at a Glance

Published: April 10, 2025

Unveiling the Green Valley Ranch East Amenity - A New Hub for Recreation and Relaxation

Published: January 21, 2025